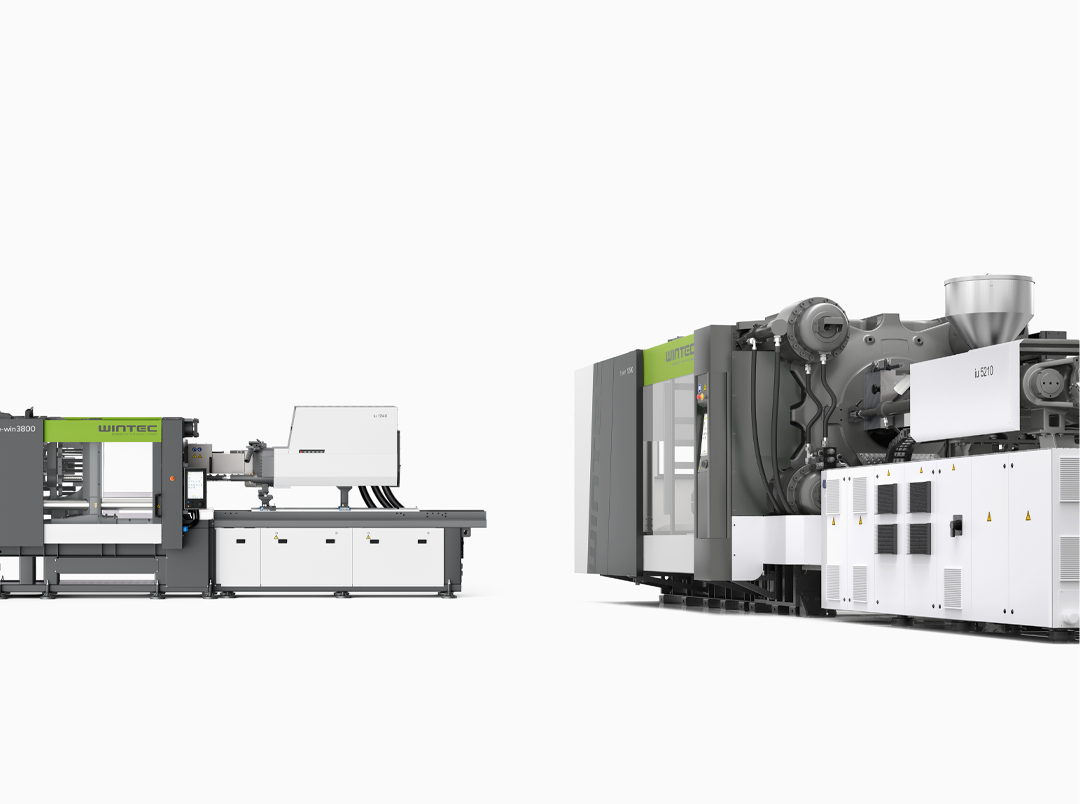

Founded in 2017 amid a wave of transformation in Chinese manufacturing, Weihai RuiMu Precision has evolved into the upcoming "hidden champion": a high-tech enterprise integrating precision mould development, injection moulding, vapor deposition, assembly, and automation, serving top clients across Europe, the U.S. , Japan, Korea, and China. Stepping into the newly operational 12,000 m2 facility in Weihai, one encounters a vision of the future:climate-controlled anti-static workshops, Class 10,000 cleanrooms, AGV forklifts, and rows of WINTEC injection moulding machines—all quietly redefining the essence of Chinese manufacturing. Founded in 2017 amid a wave of transformation in Chinese manufacturing, Weihai RuiMu Precision has evolved into the upcoming "hidden champion":a high-tech enterprise integrating precision mould development, injection moulding, vapor deposition, assembly, and automation, serving top clients across Europe, the U.S. , Japan, Korea, and China. Stepping into the newly operational 12,000 m2 facility in Weihai, one encounters a vision of the future:climate-controlled anti-static workshops, Class 10,000 cleanrooms, AGV forklifts, and rows of WINTEC injection moulding machines—all quietly redefining the essence of Chinese manufacturing.

Strategy |The Upgrade Behind a Major Investment

"In the past,'Made in China'meant 'getting things done'—quality wasn't the top priority," admitted Xiankun BI, Chairman of the group. But as global supply chains shift and competition in the mid-to-low end market intensifies, breaking through and moving upwards has become a matter of survival. Succeeding in the premium segment demands stronger capabilities across the board, and advanced equipment is the ticket to entering this league and engaging with world-class customers.

This realization crystallized after RuiMu's team visited century-old legacy German factories in late 2023. "German manufacturers plan equipment investments on 50-year cycles—that's our benchmark," noted the team. The experience led to a pivotal decision:to invest in a world-class production facility.

General Manager Zhaogang QU stressed that this was not simply about capacity expansion, but a strategic transition "from single component manufacturing to full-stack applications and assembly."As Chinese manufacturing enters an era of precision and specialization, RuiMu aims not only to produce parts, but to make "Precision Made in China"a gold standard in global supply chains.

Today, RuiMu's advanced production line — integrating water circulation, automated feeding, and robotics — delivers precision and efficiency at scale for automotive lights and printers. Powered by MES/ERP and self-developed automation solutions, it represents a new era of smart manufacturing. Central to this operation are rows of WINTEC injection moulding machines:not merely equipment, but the very foundation of RuiMu's dual commitment to superior quality and unmatched efficiency.

Facility |WINTEC's Proven Advantages: Precision, Speed, Stability and Value

RuiMu sets extremely rigorous standards for equipment selection — "only partnering with top five global suppliers"—while pursuing optimal cost-effectiveness based on high performance. Technical Director De DONG stated:"Choosing WINTEC means embracing both the technical DNA and performance assurance inherited from ENGEL, as well as WINTEC's exceptional long-term return on investment that delivers both quality and value."

DONG elaborated on WINTEC's core strengths: "WINTEC machines achieve true full closed-loop control. Every parameter — speed, pressure, position, etc. — is monitored in real time via high-precision sensors, enabling seamless human-machine coordination. We bought our first WINTEC back in 2018,today it still performs in like-new condition. Compared to many brands that show accuracy drift after five years, WINTEC outperforms and maintains its long-term precision, efficiency, and stability. Now, the exceptional reliability of our 20+ WINTEC machines gives us the confidence to promise customers ultra-fast 1-3 days delivery. For high-precision products, WINTEC delivers repeatability within 0.1%. For high-volume orders, it impresses with fast response and significantly shorter cycle times, improving efficiency by 15% while reducing energy consumption by over 20% compared to the domestic alternatives we previously used. We are impressed and pleased with the performance."

WINTEC's powerful C3 control system acts as a "smart brain, "integrating data from both injection machines and auxiliaries. It allows one-click parameter saving and accurate process replication, eliminating reprocessing and avoiding quality fluctuations caused by manual adjustments. This greatly enhances line-change efficiency and lays a solid foundation for standardized, digital production. Moreover, WINTEC's compatibility, proactive support, and professional training empower RuiMu to take on challenging high-quality orders with confidence.

ROI |The Smart Investment:The Calculus of Lasting Value

In manufacturing, every investment must ultimately prove its value through financial performance. For RuiMu, equipment selection is not a cost-based decision—it's a strategic investment for the future.

"We focus on long-term value and total cost of ownership, not short-term price. WINTEC delivers clear returns through lower costs and higher efficiency":

Cost Reduction:Exceptionally low scrap rates minimize waste, outstanding energy-saving design slashes power consumption, and unparalleled reliability reduces downtime and maintenance.

Performance Lift:Uninterrupted operation and faster cycles free up capacity, allowing RuiMu to capture more high-margin, high-volume orders and sustain scalable growth.

This is more than a procurement decision—it's a compound advantage that continues to generate growth and returns for the company.

Vision |Beyond Manufacturing:Building a Legacy with Long-Term Value

From delivering on time to delivering excellence—from competing on price to leading with value—RuiMu's journey mirrors the transformation of modern Chinese manufacturing.

"Working with global top-tier clients has taught us that century-old legacy enterprises are not built by chance," shared Chairman BI. "They are built on discipline—uncompromising standards, sustained R&D, and long-term vision."That insight now drives RuiMu's strategy:"We build facilities to last generations. We select equipment for long-term value—like WINTEC, which meets our demanding quality thresholds and supports our transition into integrated, high-quality, and smart manufacturing."Already, auxiliary systems have been standardized;automation and smart technology are being integrated across mould design, injection, and assembly. "We aim not only to make products, but to set new benchmarks—in automotive lighting, printers, smart appliances—where it matters most."

Chairman BI ended the interview by distilling the company's philosophy into a clear methodology:Simplify the complex → Standardize the simple → Process the standard → Digitalize the process → Automate the digital → Intelligize the automated.

None of this would have been possible without high-performance partners like WINTEC—machines that deliver stability, precision, and scalability, season after season. Choosing WINTEC was more than a supply chain decision. It was a meeting of values, a partnership of purpose—and a shared journey toward manufacturing that doesn't just make products, but makes history.

Customer Portal

Customer Portal

Sales & Service Contact

Sales & Service Contact