By leveraging WINTEC's injection moulding technology, Jiangsu Linquan has turned repeatability into a competitive advantage—setting new benchmarks for quality and scalability in China's fast-evolving automotive parts manufacturing market.

In the era where China's automotive industry achieves historic breakthroughs, with electric vehicles (EVs) accounting for over half of annual production and sales by 2025, Jiangsu Linquan has transformed from a traditional supplier to a core partner for the EV sector. With a 16% compound annual growth rate over three years and annual sales exceeding RMB 2 billion, Linquan stands as a benchmark in automotive interior and exterior solutions, uplifting the value of Danyang Smart Manufacturing.

Technology as the Core: Breaking the "Impossible Trio"

Faced with industry shifts like "plastic replacing steel, lightweighting, and intelligentisation," Chairman Jianlin Chen emphasises: "EVs are more cost-sensitive yet demand higher quality, design innovation, and shorter development cycles. We must systematically overcome the impossible trio of 'quality, efficiency, cost'. Our mission is to produce highly competitive, cost-effective products with superior value."

Linquan's strategy is clear: avoid low-end price wars and instead leverage technology and efficiency gains. As Chen notes, "Technology embodies our wisdom, and quality reflects our integrity. The key lies in smart upgrades and optimising the 'man, machine, material, method' system. By adopting advanced equipment like WINTEC injection moulding machines, we ensure quality, productivity, and innovation from the source."

Quality Philosophy: From "Parade Standards" to Daily Benchmarks

Linquan has spearheaded interior systems for China's National Day parades four times. Chairman Chen states, "parade level standards aren't exceptions—they're our baseline." Through rigorous control for surface finishing, dimensional stability, and innovative aesthetics, Linquan has established universal production standards.

This system, backed by reliable equipment and processes, ensures every product meets parade-level consistency, enabling scale and replication. This approach has evolved Linquan's role to co-creation with OEMs. "We now collaborate deeply from material selection and design to manufacturing, solving production challenges together." Chen adds.

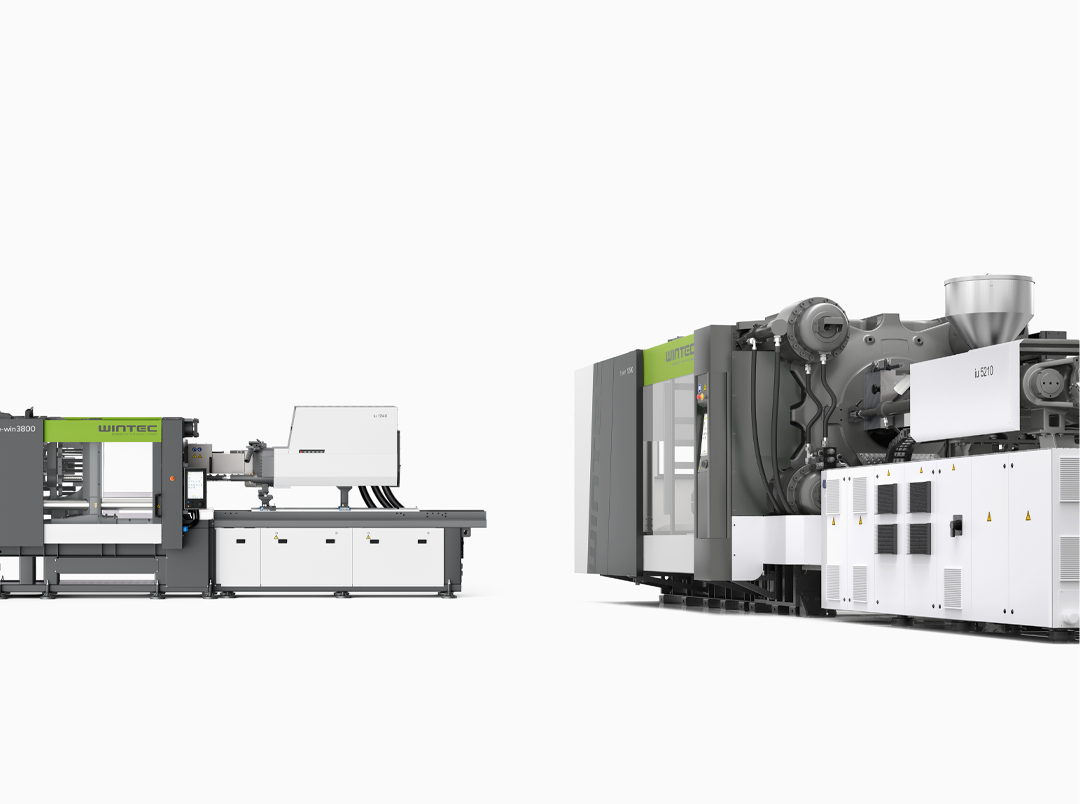

Strategic Equipment Upgrade: Why Switch to WINTEC

Equipment selection is critical to competitiveness. Production Director Xiaoyun Xu highlights, "Repeatability is of paramount importance to ensuring consistent output. WINTEC's machines achieve a repeatability of 2 ‰, a significant improvement over previous equipment." Chairman Chen elaborates on the strategic choice: "Europe still leads in advanced equipment manufacturing.

ENGEL is a trusted name, and WINTEC, as a member of the ENGEL group, inherits that excellence. We're satisfied with its stability, durability, cost-effectiveness, higher precision, and integration with systems like MES."

Technical Advantages: How WINTEC Ensures Product Consistency

In practice, WINTEC machines excel in demanding applications. Taking the automotive interior pillars as an example, Director Xu explains, "For In-Mould Decoration (IMD) processes, protecting the delicate surface decorative layer from being washed away, penetrated, or displaced—while achieving complete fusion—requires the capability of precision control in lower pressure, slower speed, multi-stage precision injection, and perfect V/P switching. At the same time, to ensure melt quality, and improve bonding strength and appearance, the temperature control system must provide highly accurate and stable heating for both the barrel and nozzle. WINTEC's injection molding machines deliver first-class performance in these aspects."

Regarding painted components, Director Xu added: "To guarantee consistent physical characteristics for every shot—avoiding issues like color variation or uneven adhesion—the injection molding machine must exhibit high stability and repeatability. To prevent material uneven mixing, which could cause surface defects, the plasticizing system must ensure uniform melting and exceptionally precise temperature control. WINTEC fully meets all of our stringent requirements—all of our painted parts are now produced using WINTEC machines."

In addition to precision and stability, WINTEC also excels in energy efficiency. "Compared to previous injection moulding machines of the same tonnage we use, WINTEC achieves 15% energy saving."

Future Outlook: Co-evolution for Industry Leadership

Looking ahead, Linquan aims to be an upgrade model for China's auto parts industry, focusing on smart, digital manufacturing.

"WINTEC's greatest value is reliability," says Chen. "We look forward to joint R&D on new models and processes—Linquan's success is WINTEC's success." This partnership exemplifies China's shift from "manufacturing" to "smart manufacturing" where technology and quality propel high-value growth.

From four machines in 2017 to forty today, WINTEC has grown alongside Linquan, providing the precision and reliability that underpin quality assurance. As globalisation and innovation accelerate, Linquan and WINTEC continue to partner for mutual success, creating unique value through shared vision and collaboration.

Customer Portal

Customer Portal

Sales & Service Contact

Sales & Service Contact