Ensuring minimal deformation under high clamping force, preComprehensive smart functions enable continuous monitoring and optimization of productionventing uneven force on tie bars, thereby maintaining production stability.

Sales & Service Contact

Sales & Service Contact

Your local contact in

Technical customer service

+43 50 620 3333

service.ea@engel.at

Spare parts sales

+43 50 620 3333

service.ea@engel.at

Support Hotline 24/7

+43 50 620 3333

Fees for the ENGEL hotline vary depending on the country. Details

Two-Platen

MACHINE TYPE

Servo-Hydraulic

DRIVE TYPE

4,500-40,000 kN

CLAMPING FORCE

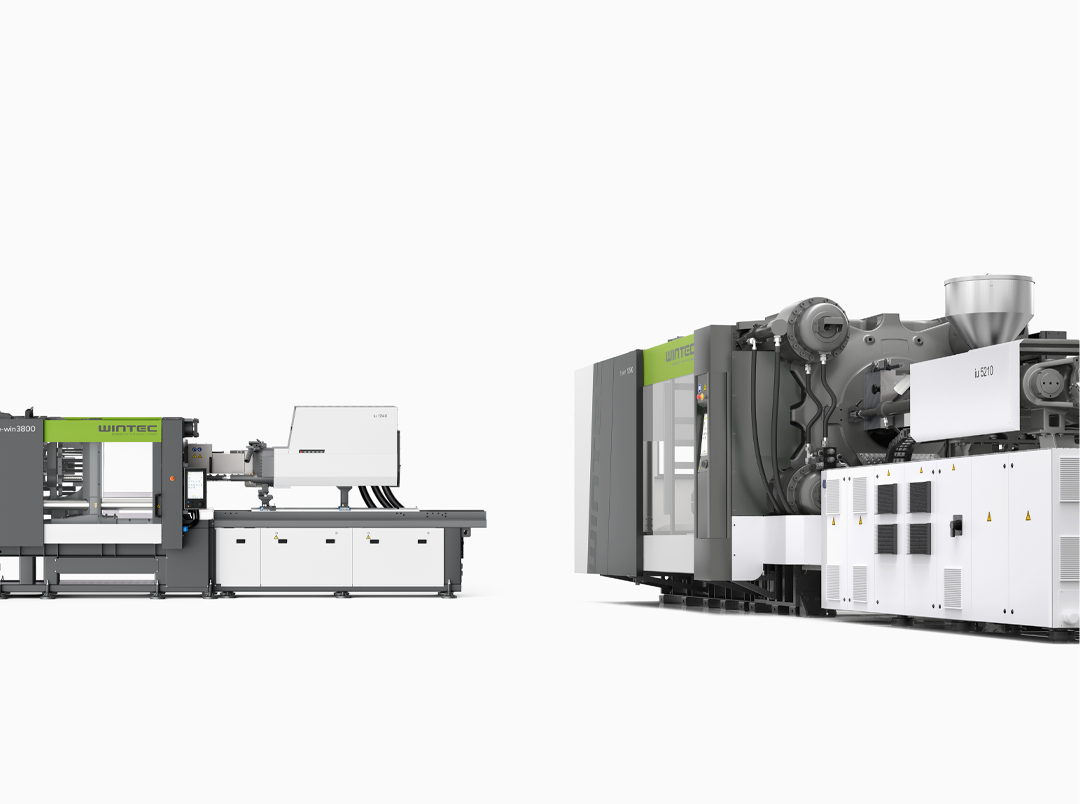

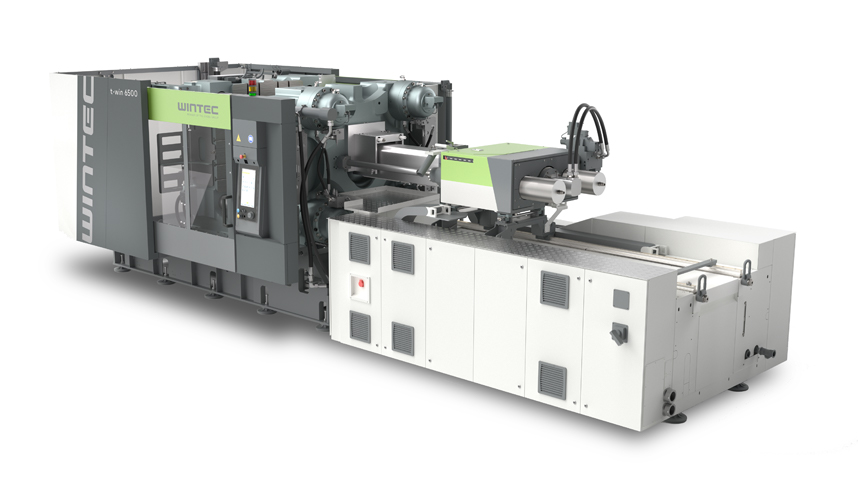

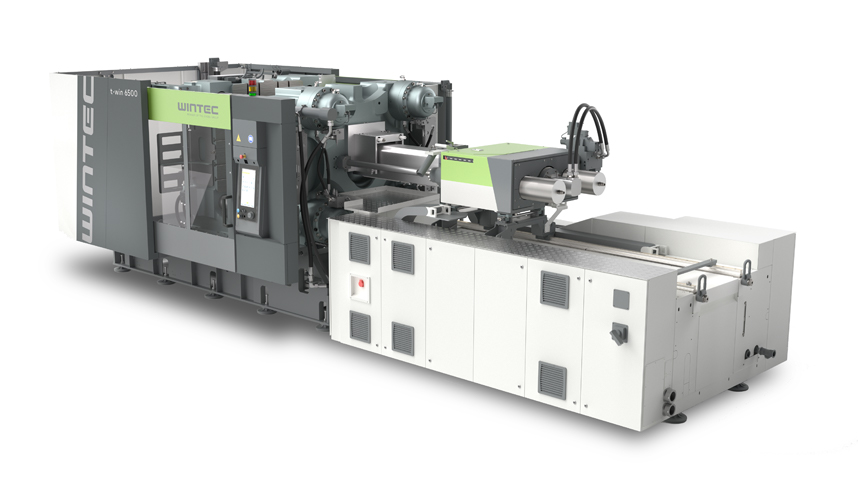

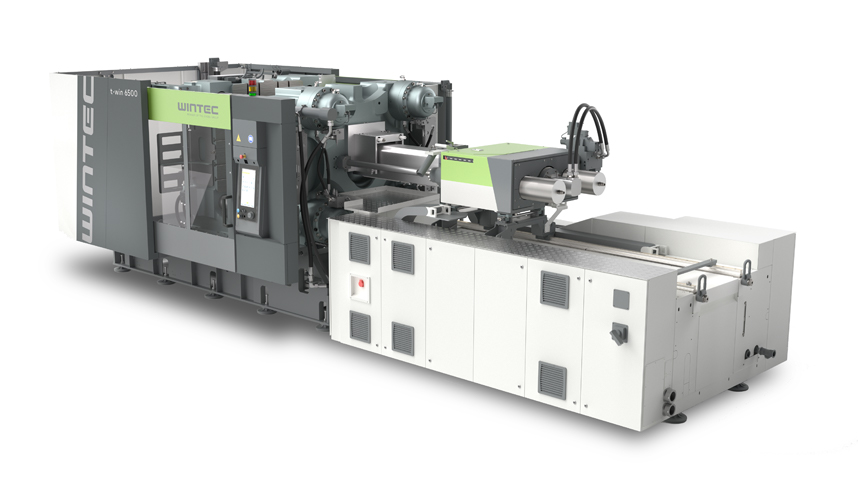

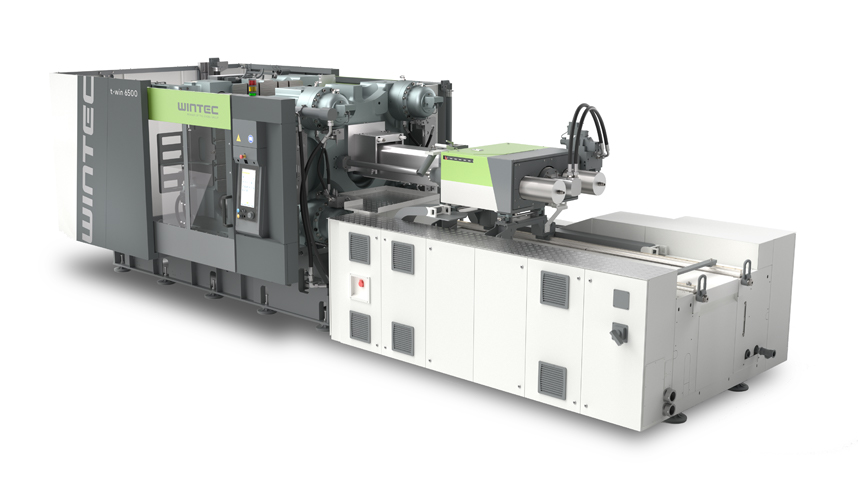

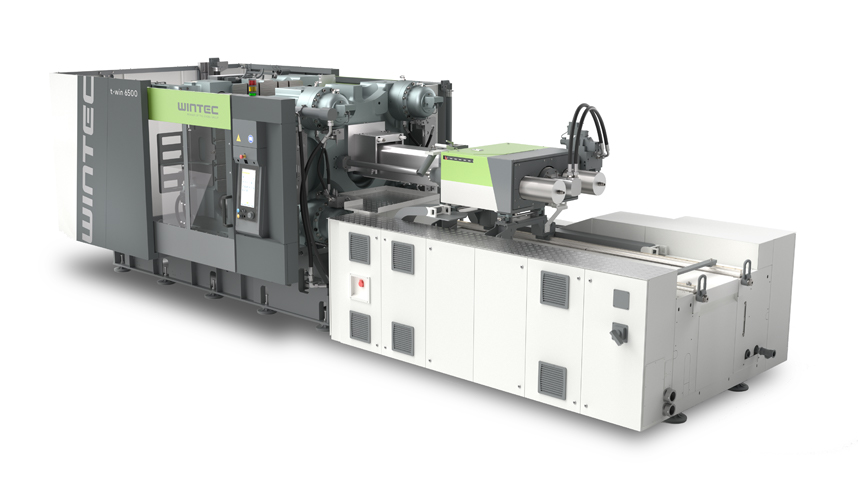

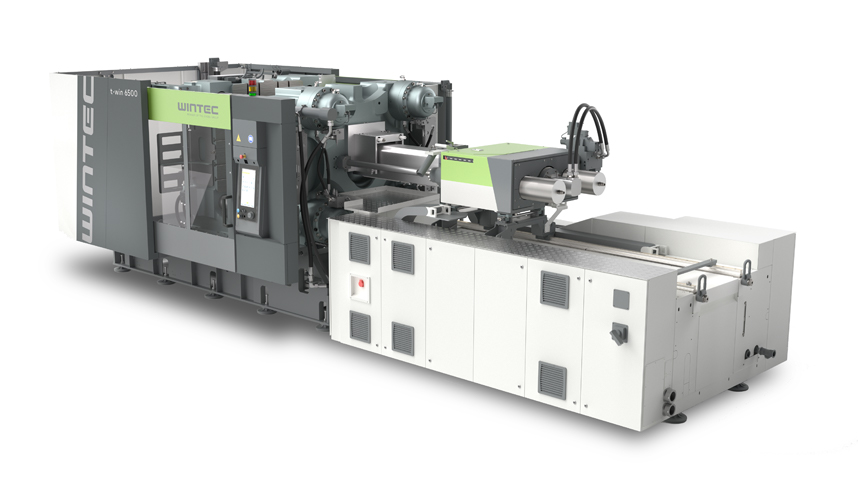

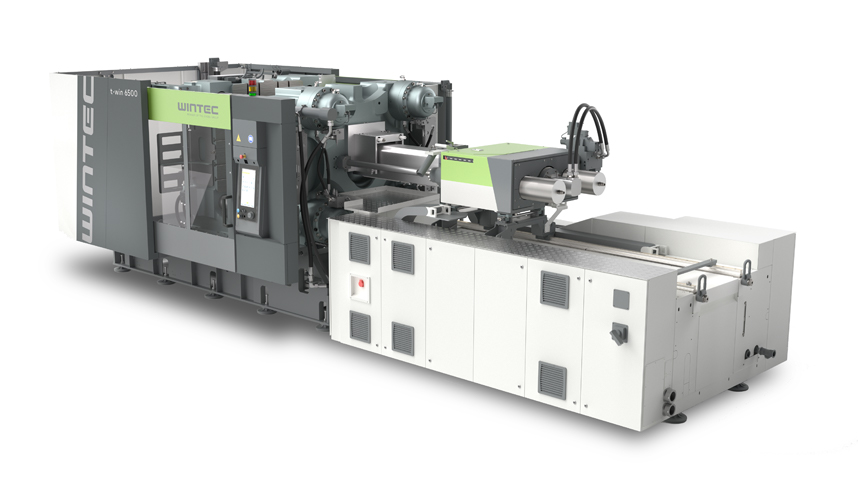

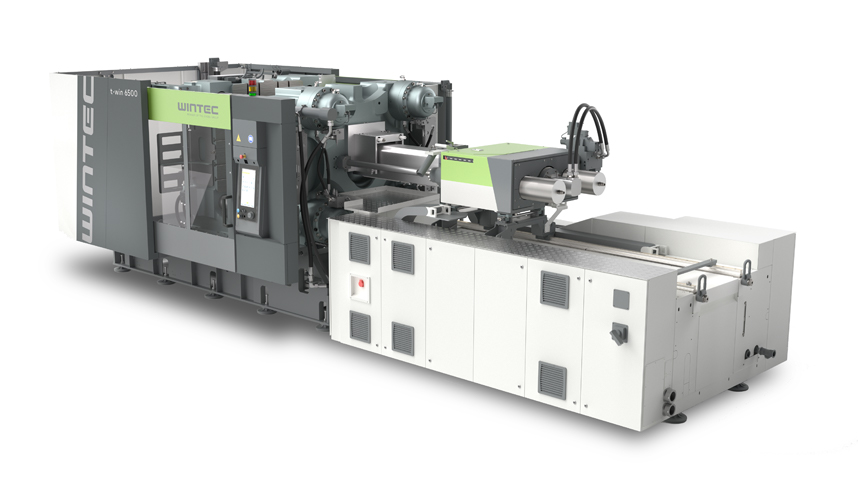

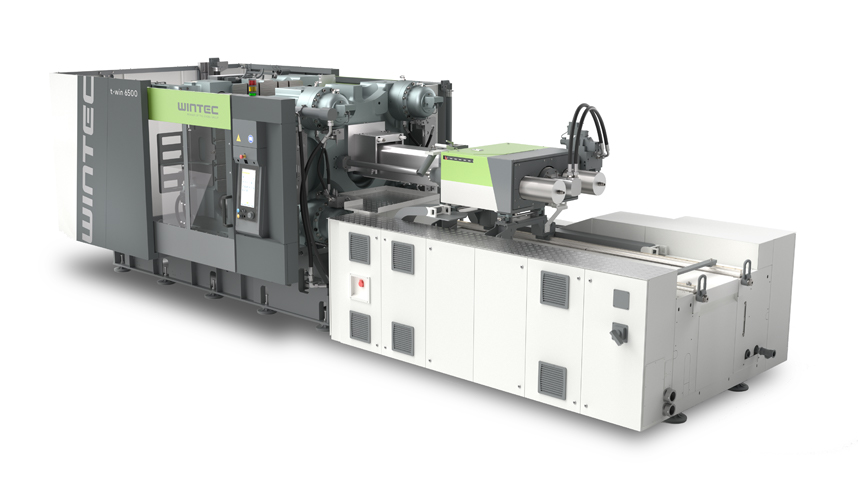

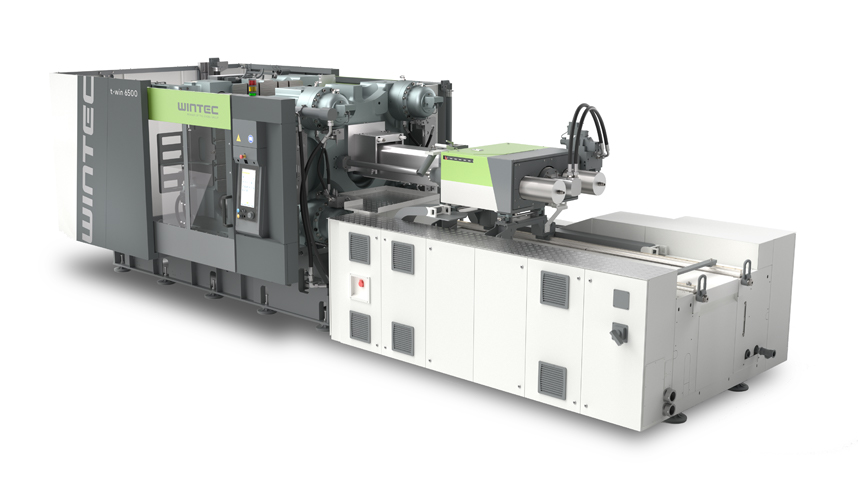

The WINTEC t-win servo-hydraulic two platen machine impresses with exceptional ROI by adapting proven innovations, offering high availability and cost-effectiveness with uncompromised stability and productivity backed by ENGEL. With focused and streamlined solutions for diverse applications from automotive, logistics, to household components, it is the smartest way to plug and inject, ideal for rapid and efficient production, delivering productivity gains, quality improvements, and sustainable long-term growth.

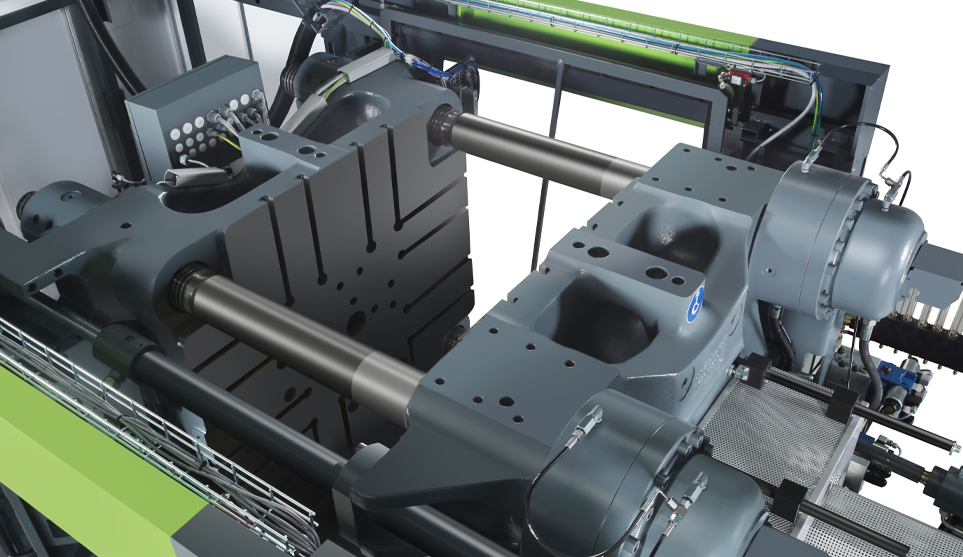

Outstanding original two platen design, ensuring exceptional stability and fast cycles through key innovations: frictionless movement between tie bars and platens, excellent platen parallelism, precise linear guides, short-stroke pressure pads, synchronized locking and rigid mechanical construction.

The C3 is an innovative machine control system with streamlined design and intuitive operation with e-move, providing smart and easy control with rigorously validated ENGEL software design and technologies. Powerful extension functions like iQ weight control provide targeted support for complex tasks.

From higher energy efficiency to faster injection speed, t-win's efficient injection unit features parallel dual-injection cylinder, compact and energy-efficient heat exchange system in electrical cabinet, barrel heating system with multi-zone closed-loop PID temperature control, high wear-resistant screw, barrel, and NRV.

Servowin: the powerful hydraulic drive system ensures an energy-efficient production. Its compact design and short setup times enhance flexibility and productivity.

Ensuring minimal deformation under high clamping force, preventing uneven force on tie bars, thereby maintaining production stability.

High precision sensors are integrated into various functional zones—such as clamping, injection, mold height adjustment, and injection unit movement—enabling real-time monitoring of actual operational values. Data collected by these sensors is fed back to the control system, allowing dynamic parameter optimization for high precision repeatability and operational stability across all processes.

Tested and verified with maximum clamping force and maximum injection pressure of 3 million cycles.

900+ check points pre-delivery, ensuring uncompromised quality and reliability.

Simulated by FEA (Finite Element Analysis), leveraging ENGEL’s FEA experience of more than 30 years.

Ensuring stable pressure and speed while minimizing cycle-to-cycle variation.

Significantly reducing melt temperature fluctuations and helps prevent material degradation or inconsistent plasticization.

Ensuring enhanced durability and consistent plasticizing performance.

Designed with enhanced capabilities to deliver faster injection speeds and higher maximum injection pressure, ensuring superior performance and efficient injection across a wide range of materials.

Simple and efficient interlock design features that enables buffered damping instead of uniform high-speed impact, resulting in lower friction, faster action, higher energy efficiency, and greater stability.

With much greater power density, Servowin needs much less oil consumption, which achieves smaller component sizes and faster response times, while delivering much greater pressure and increase much higher efficiency, as well as improved control precision.

Reducing motion time for faster cycle time and enhanced production efficiency.

High precision sensors are integrated into various functional zones—such as clamping, injection, mold height adjustment, and injection unit movement—enabling real-time monitoring of actual operational values. Data collected by these sensors is fed back to the control system, allowing dynamic parameter optimization for high precision repeatability and operational stability across all processes.

Contactless design featuring zero contact between tie bars and platen: frictionless movement ensuring higher precision and speed, less energy consumption.

Linear guides can secure lower friction compared to slide guide, resulting in lower energy consumption, higher accuracy, faster dynamic responsiveness.

*Contact sales for available clamping unit

High stiffness platen, combined with precise machining and controlled commissioning, delivers exceptional parallelism accuracy.

Real-time software monitoring of platen parallelism ensures visibility and control during production, effectively safeguarding molding quality and equipment stability.

Unlike traditional gear pump systems with fixed oil displacement per rotation—limiting control to motor speed adjustment—WINTEC’s variable displacement pump enables precise oil volume control per rotation via simultaneous motor speed and swashplate angle modulation. This eliminates pulsation and noise while maximizing efficiency, especially ideal for applications requiring extended holding times.

Linear guides can secure lower friction compared to slide guide, resulting in lower energy consumption, higher accuracy, faster dynamic responsiveness.

*Contact sales for available clamping unit.

Higher hydraulic system pressure enables a more compact structural design and energy-efficient machine operation.

Display of energy consumption for last and current cycle, monitoring and analysing real-time energy consumpation.

Compared to ceramic heating bands, infrared heating bands offer significant improvements in energy savings.

*Optional.

WINTEC features an advanced, future-oriented control system developed by ENGEL. Built on over 80 years of industry-leading expertise in injection moulding, it delivers exceptional flexibility and adaptability, along with more powerful and precise control—fully meeting demands for high efficiency and accuracy in production. This system is a key technological foundation for the high performance, precision, and stability of WINTEC injection moulding machines. Its intuitive and user-friendly UI/UX design further enhances operational efficiency and comfort.

Comprehensive smart functions enable continuous monitoring and optimization of production quality, efficiency, and operational stability. For example, the precision mould protection combined with auto-project injection monitoring and program parameter limits offer smart and precise mould protection.

iQ weight control, iQ clamp control, iQ hold control…… Additional Digital Solutions enable further control improvement and performance optimization across production efficiency, energy efficiency, scrap rate, cycle time and mould protection.

e-move one-touch operation & configurable favorite navigation allowing for more intuitive and streamlined control experience.

Heavy-duty structures (tie bars, platens, frame, etc.) , designed for infinite fatigue life.

Maintaining the cleanness of the hydraulic system, prolonging component lifespan, and maximizing operational efficiency.

Ensuring the machine maintains an optimal operating condition throughout prolonged operation.

Excellent heat dissipation performance and a high degree of sealing, effectively maintaining stable internal thermal conditions by expelling heat in a timely manner and preventing dust ingress, allowing electrical components to operate in a clean and temperature-stable environment, significantly extending their service life.

The compact two platen design features a simplified structural architecture compared to conventional three platen machines, achieving a significantly reduced footprint and enhanced spatial efficiency for optimized production floor flexibility.

Parallel dual-cylinder injection system layout for more compact structure.

Enabling a more compact structural design and enhances energy efficiency during machine operation.

The automatic lubrication system, complemented by easily accessible manual lubrication points, significantly reduces maintenance time.

Streamlined online support—from quick start to expert troubleshooting—simplifies operation and maximizes efficiency. Real-time alarm decoding provides instant solutions to minimize downtime.

Easy to operate and maintain

Portrait 1920*1080: Bigger display area

Modular architecture streamlines production and accelerates delivery, offering faster time-to-market.

A strategic inventory of materials that have extended procurement cycles, ensuring production continuity and mitigating supply chain risks, accelerating delivery.

Sufficient inventory of stock machines, enabling quick delivery.

Industry-leading stability, precision, efficiency, and availability, guaranteeing you meet your customers' requirements cycle by cycle, and exceeding your customers' expectations project by project.

Lower scrap rate: Lower waste

Less energy consumption

Less malfunction: Lower cost for maintenance

Longer lifetime: Less depreciation

Superior Stability

High-Strength Frame & High-Stiffness Platens

Ensuring minimal deformation under high clamping force, preComprehensive smart functions enable continuous monitoring and optimization of productionventing uneven force on tie bars, thereby maintaining production stability.

Full Closed-Loop Control with High Precision Sensors

High precision sensors are integrated into various functional zones—such as clamping, injection, mold height adjustment, and injection unit movement—enabling real-time monitoring of actual operational values. Data collected by these sensors is fed back to the control system, allowing dynamic parameter optimization for high precision repeatability and operational stability across all processes.

Rigorous Testing Ensuring Superior Stability

Tested and verified with maximum clamping force and maximum injection pressure of 3 million cycles.

900+ check points pre-delivery, ensuring uncompromised quality and reliability.

Simulated by FEA (Finite Element Analysis), leveraging ENGEL’s FEA experience of more than 30 years.

Responsive Hydraulic Valves and High-Precision Piston Pumps

Ensuring stable pressure and speed while minimizing cycle-to-cycle variation.

Barrel Heating System with Multi-Zone Closed-Loop PID Temperature Control

Significantly reducing melt temperature fluctuations and helps prevent material degradation or inconsistent plasticization.

High Wear-Resistant Screw, Barrel, and NRV

Ensuring enhanced durability and consistent plasticizing performance.

World-class Efficiency

Powerful Hydraulic Servo System

Designed with enhanced capabilities to deliver faster injection speeds and higher maximum injection pressure, ensuring superior performance and efficient injection across a wide range of materials.

Synchronized Locking

Simple and efficient interlock design features that enables buffered damping instead of uniform high-speed impact, resulting in lower friction, faster action, higher energy efficiency, and greater stability.

Industry-Leading Hydraulic System Pressure

With much greater power density, Servowin needs much less oil consumption, which achieves smaller component sizes and faster response times, while delivering much greater pressure and increase much higher efficiency, as well as improved control precision.

Short-Stroke Pressure Pad

Reducing motion time for faster cycle time and enhanced production efficiency.

Outstanding Precision

Full Closed-Loop Control with High Precision Sensors

High precision sensors are integrated into various functional zones—such as clamping, injection, mold height adjustment, and injection unit movement—enabling real-time monitoring of actual operational values. Data collected by these sensors is fed back to the control system, allowing dynamic parameter optimization for high precision repeatability and operational stability across all processes.

Contactless Tie Bar

Contactless design featuring zero contact between tie bars and platen: frictionless movement ensuring higher precision and speed, less energy consumption.

* Precise Linear Guide

Linear guides can secure lower friction compared to slide guide, resulting in lower energy consumption, higher accuracy, faster dynamic responsiveness.

*Contact sales for available clamping unit

Excellent Platen Parallelism

High stiffness platen, combined with precise machining and controlled commissioning, delivers exceptional parallelism accuracy.

Real-time software monitoring of platen parallelism ensures visibility and control during production, effectively safeguarding molding quality and equipment stability.

Higher Energy Saving

Powerful Hydraulic Servo System with Servo Motor + Variable Displacement Pump

Unlike traditional gear pump systems with fixed oil displacement per rotation—limiting control to motor speed adjustment—WINTEC’s variable displacement pump enables precise oil volume control per rotation via simultaneous motor speed and swashplate angle modulation. This eliminates pulsation and noise while maximizing efficiency, especially ideal for applications requiring extended holding times.

* Precise Linear Guide

Linear guides can secure lower friction compared to slide guide, resulting in lower energy consumption, higher accuracy, faster dynamic responsiveness.

*Contact sales for available clamping unit.

Higher Hydraulic System Pressure

Higher hydraulic system pressure enables a more compact structural design and energy-efficient machine operation.

Ecograph

Display of energy consumption for last and current cycle, monitoring and analysing real-time energy consumpation.

Infrared Heating Band *

Compared to ceramic heating bands, infrared heating bands offer significant improvements in energy savings.

*Optional.

Smarter Control

Future-Oriented Technologies

WINTEC features an advanced, future-oriented control system developed by ENGEL. Built on over 80 years of industry-leading expertise in injection moulding, it delivers exceptional flexibility and adaptability, along with more powerful and precise control—fully meeting demands for high efficiency and accuracy in production. This system is a key technological foundation for the high performance, precision, and stability of WINTEC injection moulding machines. Its intuitive and user-friendly UI/UX design further enhances operational efficiency and comfort.

Powerful Smart Functions

Comprehensive smart functions enable continuous monitoring and optimization of production quality, efficiency, and operational stability. For example, the precision mould protection combined with auto-project injection monitoring and program parameter limits offer smart and precise mould protection.

iQ weight control, iQ clamp control, iQ hold control…… Additional Digital Solutions enable further control improvement and performance optimization across production efficiency, energy efficiency, scrap rate, cycle time and mould protection.

e-move One-Touch Operation & Configurable Favorite Navigation

e-move one-touch operation & configurable favorite navigation allowing for more intuitive and streamlined control experience.

Longer Lifetime

High-Strength Structural Design with Infinite Fatigue Life

Heavy-duty structures (tie bars, platens, frame, etc.) , designed for infinite fatigue life.

High-Precision Hydraulic Filtration System

Maintaining the cleanness of the hydraulic system, prolonging component lifespan, and maximizing operational efficiency.

Automatic Lubrication System

Ensuring the machine maintains an optimal operating condition throughout prolonged operation.

Powerful Heat Exchange System in Electrical Cabinet

Excellent heat dissipation performance and a high degree of sealing, effectively maintaining stable internal thermal conditions by expelling heat in a timely manner and preventing dust ingress, allowing electrical components to operate in a clean and temperature-stable environment, significantly extending their service life.

Compact Design

Compact Two Platen Design

The compact two platen design features a simplified structural architecture compared to conventional three platen machines, achieving a significantly reduced footprint and enhanced spatial efficiency for optimized production floor flexibility.

Parallel Injection Cylinder

Parallel dual-cylinder injection system layout for more compact structure.

Higher Hydraulic System Pressure

Enabling a more compact structural design and enhances energy efficiency during machine operation.

Easy To Use

Integrated Lubrication

The automatic lubrication system, complemented by easily accessible manual lubrication points, significantly reduces maintenance time.

Online Tutorials, Helpdesk and Alarm Explanation

Streamlined online support—from quick start to expert troubleshooting—simplifies operation and maximizes efficiency. Real-time alarm decoding provides instant solutions to minimize downtime.

Large Mould Space

Easy to operate and maintain

15″- Full HD Display

Portrait 1920*1080: Bigger display area

Faster Delivery & Deployment

Modular Design & Manufacturing

Modular architecture streamlines production and accelerates delivery, offering faster time-to-market.

Stock for Long-Lead-Time Parts

A strategic inventory of materials that have extended procurement cycles, ensuring production continuity and mitigating supply chain risks, accelerating delivery.

Sufficient Stock Machines

Sufficient inventory of stock machines, enabling quick delivery.

Better Total Cost of Ownership

Increased Productivity

Industry-leading stability, precision, efficiency, and availability, guaranteeing you meet your customers' requirements cycle by cycle, and exceeding your customers' expectations project by project.

Cost Reduction

Lower scrap rate: Lower waste

Less energy consumption

Less malfunction: Lower cost for maintenance

Longer lifetime: Less depreciation