iQ weight control

Summary: Compensate for Material Viscosity Fluctuations Automatically

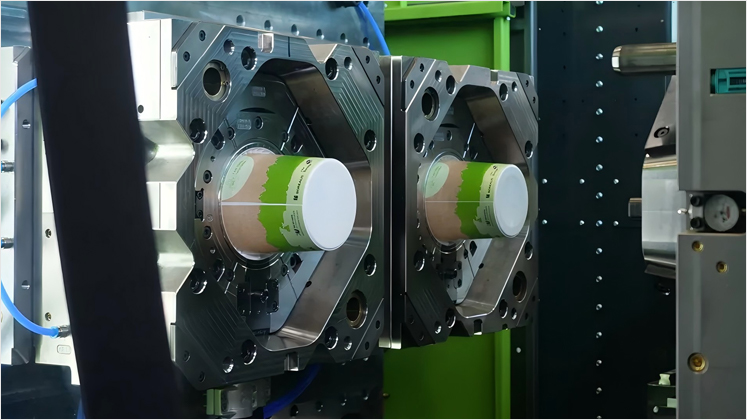

This intelligent digital solution maintains constant part weight by dynamically regulating the injection volume during the ongoing process. It compares the injection pressure curve of each cycle with a predefined reference curve, automatically compensating for variations in plastic viscosity.

Your Key Benefits:

Up to 50% Scrap Reduction: Achieve remarkable consistency, drastically lowering your reject rate.

66% Higher Process Stability: Ensure repeatable quality, cycle after cycle.

100% Suitable for Recycling: Perfectly suited for processing recycled plastics with inherent viscosity variations.

Customer Portal

Customer Portal

Sales & Service Contact

Sales & Service Contact