In Taizhou Huangyan—China's "mould manufacturing heartland"—the injection moulding industry once created countless success stories, but it also underwent a shift from rapid growth to intense internal competition. As more players entered the market, homogeneous low-price competition became the norm. The pandemic accelerated this transformation, weeding out small manufacturers that lacked core competitiveness.

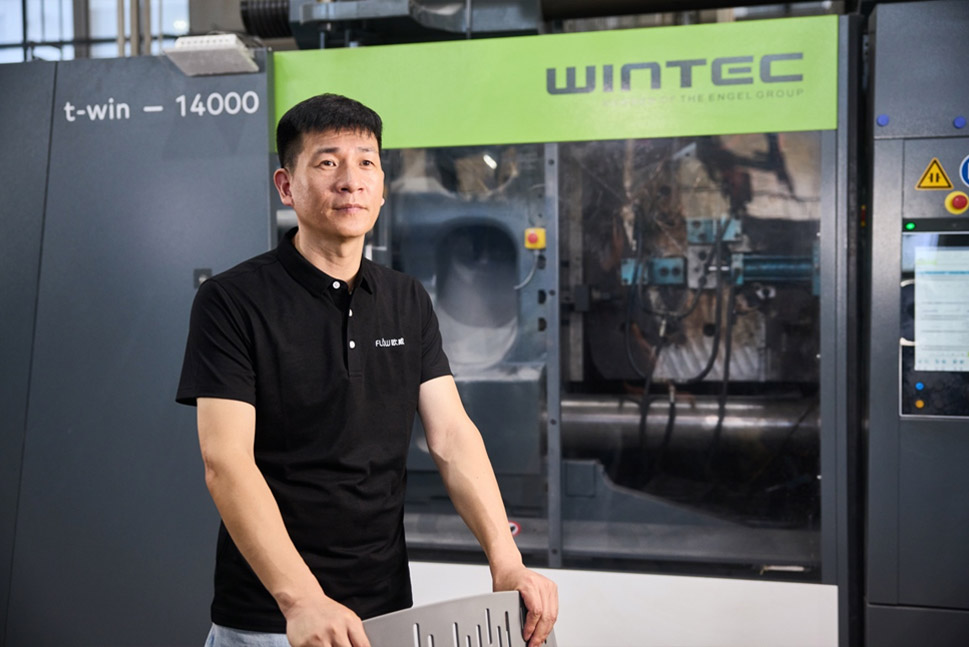

In this high-stakes environment, Ouwei Furniture's founder Minzhi HUANG—a self-made mould apprentice who grew up amid the whir of mould-making workshops—refused to play the old game.

Instead of joining the price war, he charted a different course: upgrade, innovate, lead—not to race to the bottom, but to climb to the top.

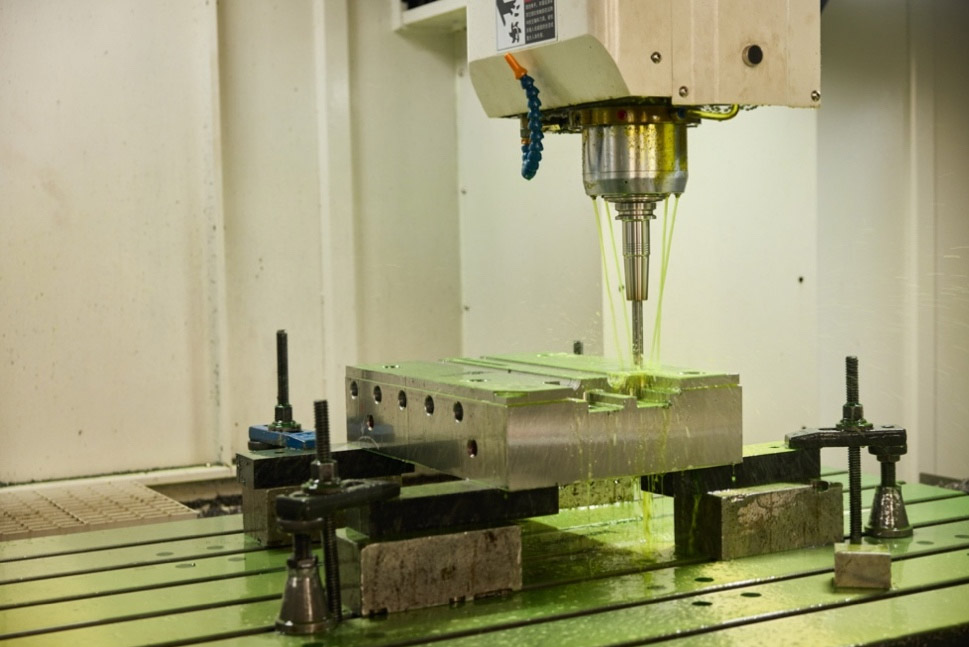

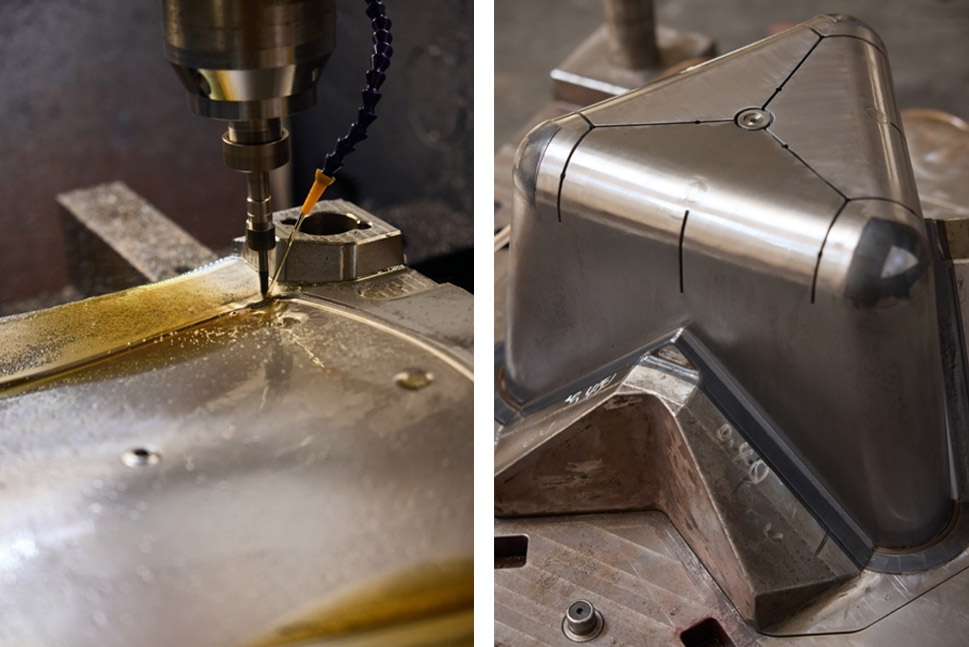

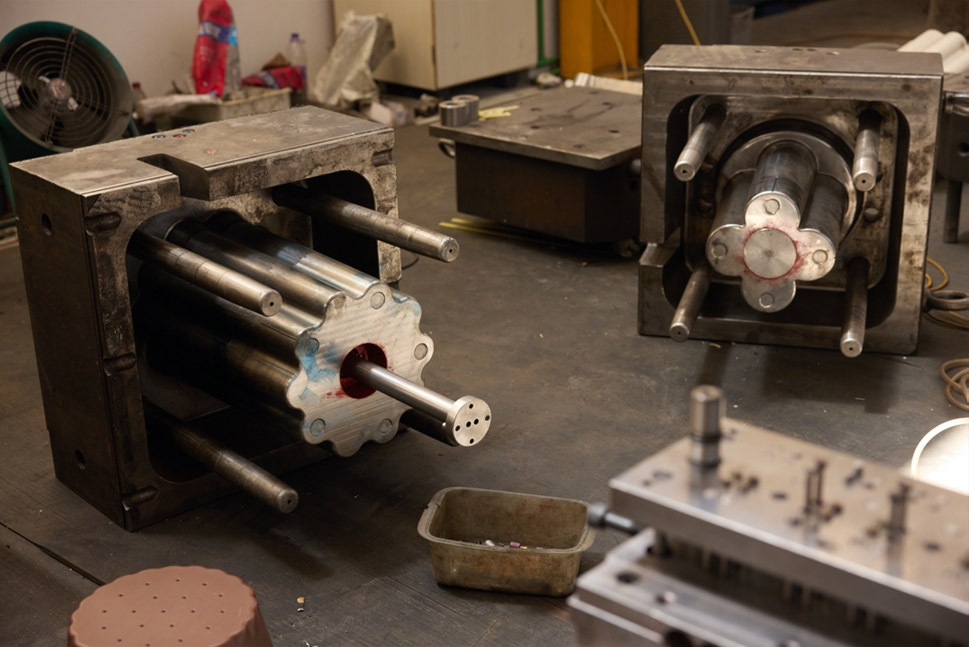

Roots: A Foundation Built on Mould-Making Expertise

Decades of mould-making flow in Ouwei's DNA. Mr. Huang's hands-on experience gave Ouwei an almost intuitive grasp of material, structure, and precision—a foundation so solid that global brands soon took notice. OEM contracts followed, with 70% of Ouwei's output destined for Europe and the U.S.

But OEM, Huang knew, was a starting line, not the finish. To escape the commoditisation trap, Ouwei would need its own voice, its own brand.

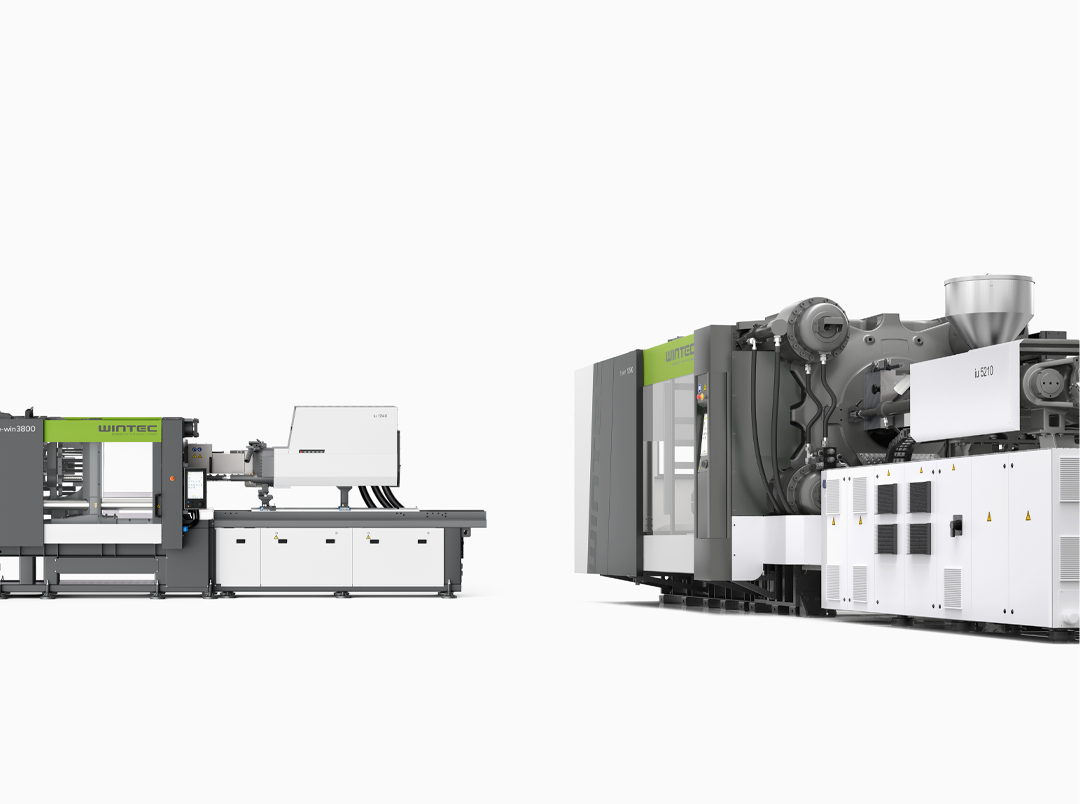

Upgrade: WINTEC Injection Moulding Machines

—The "Stabiliser" of Speed and Quality

Ouwei's growth philosophy is embodied in the WINTEC injection moulding machines it has used for eight years. Before introducing WINTEC, Ouwei's production line faced persistent challenges, from surface flaws like flow marks and shrinkage, varying structural strength, to fluctuating scrap rates. These issues not only increased reprocessing and rework costs but also delayed deliveries, limiting Ouwei's ability to take on high-demand orders. "We faced a dilemma: ensuring surface finish and dimensional accuracy meant sacrificing efficiency, while chasing output led to quality fluctuations, " Mr. Huang recalled. " This was especially apparent when meeting the high consistency requirements of international clients."

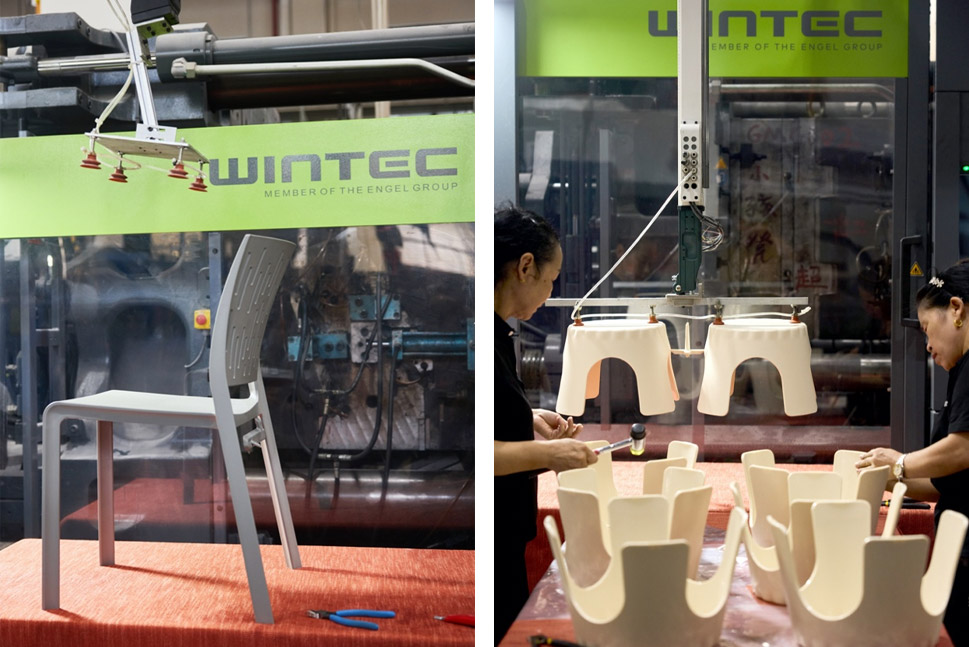

The turning point came with the first WINTEC injection moulding machine. Over the past seven to eight years, the equipment has delivered impressive results:

Efficiency Leap

WINTEC reduced the cycle time from 120 seconds to between 100 – 110 seconds—a nearly 10% gain in efficiency. In an industry where every second counts, this meant higher output and lower unit costs.

Quality Transformation

More important than speed was the leap in quality. "Once the machine is set, there's almost no scrap," said Mr. Huang. "Products come out smooth and firm right out of the machine—essentially minimal trimming needed." This "right-the-first-time" stability allows Ouwei to confidently tackle high-difficulty, high-appearance orders.

Cost Structure Optimisation

Less scrap, fewer man-hours in rework, and more reliable deliveries—WINTEC's impact goes beyond machine performance. It has reshaped Ouwei's cost structure, enabling the company to escape the "sacrifice quality for price" trap and compete instead on superior value and reliability.

"Today, we can guarantee speed, precision, and stability at the same time," Mr. Huang concluded. That reliability didn't just save seconds—it built trust. While rivals fought over pennies, Ouwei delivered premium quality without the premium cost. "That is the foundation of Ouwei's move into the premium market."

Breakthrough: Designing at the Speed of Relevance

"A hit product used to earn for a year, sometimes two," Huang reflects. "Now? You have six months—maybe less—before copies flood the market and margins vanish."

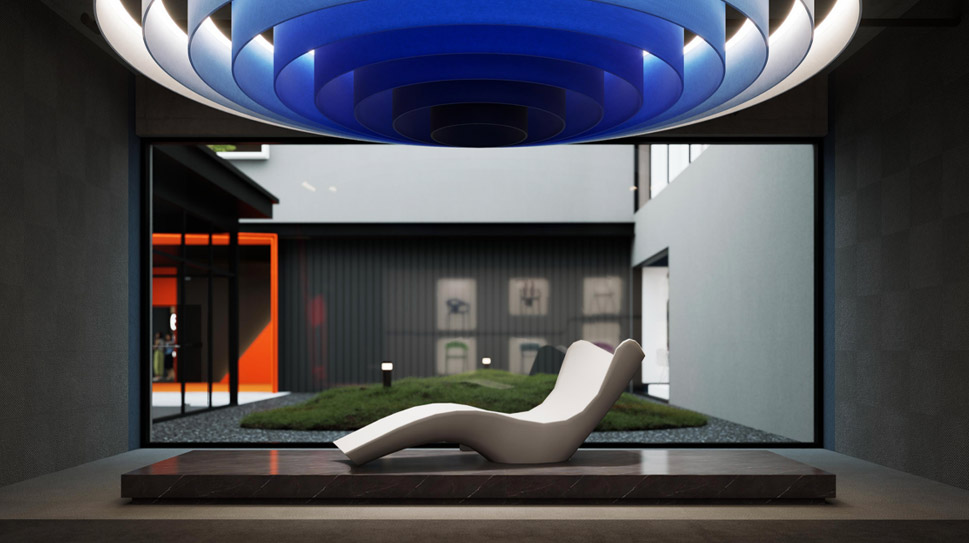

Ouwei's counterpunch is a design-led, speed-to-market strategy. While competitors chase last quarter's bestseller, Ouwei's in-house team launches original collections tailored for today's lifestyles: sleek indoor pieces, weather-resistant outdoor sets, commercial solutions for cafes, pools and retail spaces…

While others commoditise, Ouwei connects with life's precious moments—and during those first months after launch, before imitation even begins, Ouwei secures margins worthy of innovation.

Growth: A Global Furniture Brand in the Making

Every investment Ouwei makes—in technology, equipment, talent, or process—serves one goal: delivering greater value to customers.

"We strive to offer superior product, fair price, thoughtful service. That's how you earn customers for life," says Huang. This philosophy forms the foundation of a healthy business cycle.

With a new 70,000 m² factory getting ready to hum with productivity and a brand belief ready to resonate across continents, Ouwei is no longer just a manufacturer. It's a next-generation lifestyle brand ready for the world stage.

As Mr. Huang and his long-term WINTEC partner reaffirmed their commitment to "cooperation and shared success," it was clear that this partnership is not just about maintaining the status quo—it's about driving the next phase of upgrade in equipment, capacity, and brand.

Ouwei's story illustrates a broader industrial transformation taking place in Huangyan. In an age of volatility & disruption, Ouwei and WINTEC are writing a new playbook—one where courage and capability turn market challenges into lasting opportunities.

Customer Portal

Customer Portal

Sales & Service Contact

Sales & Service Contact