ENGEL Asia successfully hosted the Logistics Day 2025 at the ENGEL Changzhou plant with its WINTEC injection molding solutions taking center stage. The event brought together the ENGEL global experts,industry leaders,and logistics manufacturing partners to explore the latest practices and development trends of injection molding technology aimed at enhancing efficiency,sustainability,and digital integration in logistics applications. Live demonstrations,technical presentations,and panel discussions highlighted advanced solutions for logistics applications using high-percentage recycled materials.

Seminar: Focusing on Frontier Topics in Logistics Injection Molding

In logistics,the trend is moving strongly towards plastic solutions for large and durable products such as crates &boxes,pallets and containers for food and non-food applications. Plastics offer clear advantages over wood and cardboard: they are easy to clean,stable in shape,less prone to damage,and highly hygienic. By combining the strengths of other materials while avoiding many of their weaknesses,plastics have become the preferred choice for modern logistics.

Facing the rising demands of the logistics industry for fast delivery,consistent quality,controllable costs and sustainability,injection molding sector is playing an increasingly crucial role. Dr. Stefan Engleder,CEO of the ENGEL Group,emphasized in his opening address: "With over 80 years of expertise and experience,we at ENGEL are one of the leading injection molding machine manufactures and offering complete solutions for any kind of plastics applications,innovative technologies,robotics and customized system solutions from a single source."

Presentations from industry specialists covered several critical themes such as material innovation,process breakthroughs,and green recycling in logistics.

Mr. Sun Xijun,Secretary-General of China Federation of Logistics &Purchasing,outlined evolving trends in China's logistics sector and pallet industry,pointing out that efficiency,standardization,and green transformation have become core development directions for logistics carriers.

Mr. Daniel Wan,Asia Business Development Manager of BU technical molding,ENGEL,detailed the end-to-end solutions from ENGEL and WINTEC for logistics carriers,including multi-material processing,smart control systems,and automation solutions.

Mr. Jiang Jianhua,General Manager of Zhejiang Jingkai Molding Technology shared practical experiences on achieving green and low-carbon logistics carriers in production,particularly the high-percentage recycled material applications and thin-wall lightweighting.

Ms. Eva Zhou,Logistics and Packaging Technology Manager at ExxonMobil Asia Pacific,presented innovative polypropylene-based material solutions supporting circular economy goals in packaging.

Mr. Li Yunquan,Expert from the International Pallet Standards Committee,analyzed the pathways for the high-value reuse of waste plastics from the perspectives of standardization and industrialization.

Mr. Patrick Grüner,Business Development Director of BU technical molding,ENGEL,elaborated on the application of foaming and recycled material modification technologies in logistics products.

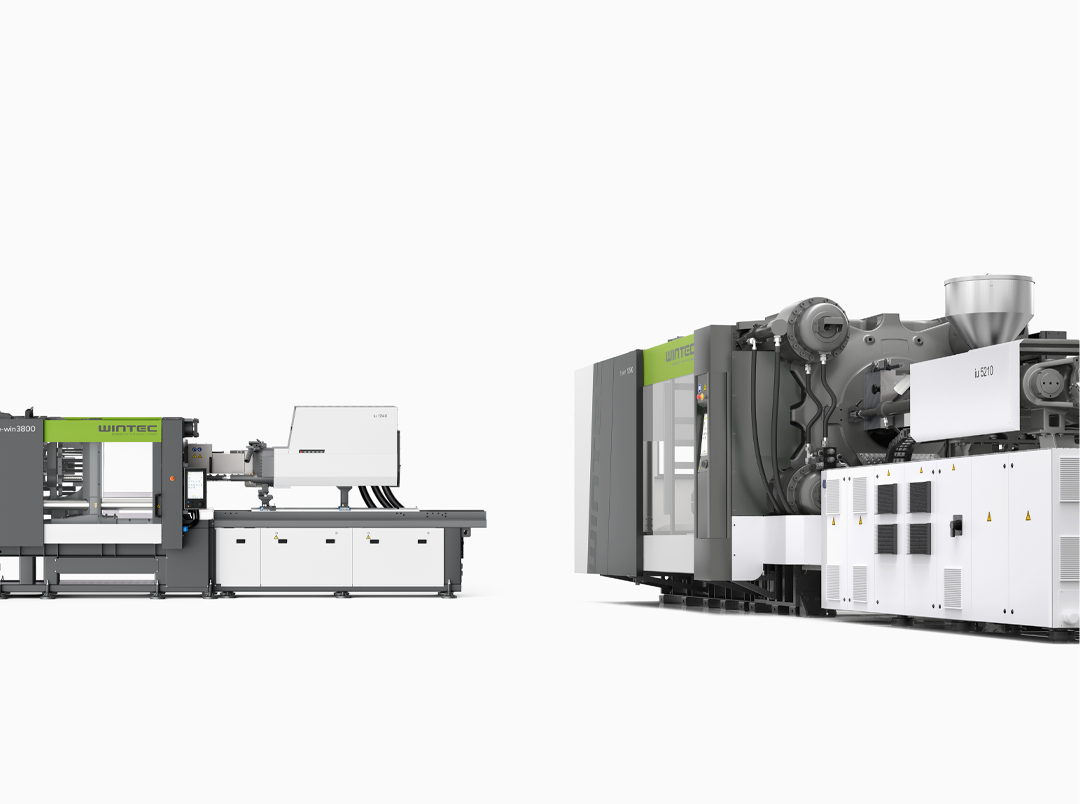

Live Demonstrations of production cell with WINTEC t-win machines: Efficient and Advanced Injection Molding Solutions

Relying on its stability,precision,efficiency,and optimal total cost of ownership,the WINTEC t-win two-platen hydraulic injection molding series demonstrated its capability to deliver high output,consistent part quality,and maximum machine availability in the logistics. Three production cells were showcased:

Three Skid Pallet: WINTEC t-win 27000-43210 showcased the production of three skid plastic pallets. From sprue cutting,rubber pad inserting till stacking all post-sequence processes was fully automated by the ENGEL automation cell. Targeted for the Logistics industry,this production cell proves how the challenges of low energy consumption,production efficiency,stable quality and cost effectiveness can be best mastered.

Nine Feet pallet: Combining the t-win 18000-21910 with an a-win 1900 linear robot,this compact production cell prepared the pallets ready for pick up,demonstrated the flexibility and stability of multi-action synchronous control,making it particularly suitable for flexible production of small and medium-sized pallets in multiple batches.

Turnover box: The t-win 10500-8210 demonstrated on the production of a turnover box,how iQ weight control can compensate fluctuating material conditions and ensure therewith stable process and part quality. The efficient production cell was completed with a WINTEC automation solution including post cooling station that allows faster demolding and reduced cycle times.

Plant Tour: Advanced Manufacturing and High-Precision Assurance

As the 9th plant of the ENGEL Group,Changzhou plant provides high precision for machining and assembly by taking ground source heat pump technology and 22℃ constant temperature workshops. It has leading automated assembly line for injection molding machines in China,which is connected to SAP management system for real-time monitoring. Machining and testing equipment uses high-end brands to ensure the quality of parts.

The event concluded with strong engagement from attendees,reflecting broad industry interest in smart,sustainable manufacturing technologies for the logistics sector.

Customer Portal

Customer Portal

Sales & Service Contact

Sales & Service Contact